Equipment for all stages of processing meat, fish, poultry and milk

Slaughter and poultry processing: acceptance of live poultry, slaughter and evisceration lines of poultry

Cutting of meat and poultry: lines for cutting birds, cutting conveyors and saws

Poultry boning in automatic and semi-automatic mode: machines for boning the breast, thighs, drumstick and the whole leg of a bird

Defrost: Defroster

Department of meat from bones: meat and bone separators and presses

Production of flake ice: ice makers and ice storage systems

Production of delicacies: injectors for meat, fish and poultry, massagers, brine mixers and filter units

Cutting of frozen blocks: block cutters

Сutters, tops, mixers

Portioning, clipping: syringes, clippers

Thermal treatment and smoking: smoking chambers, cooking chambers, intensive cooling chambers, climatic chambers and chambers for drying, chips and sawdust for smoking

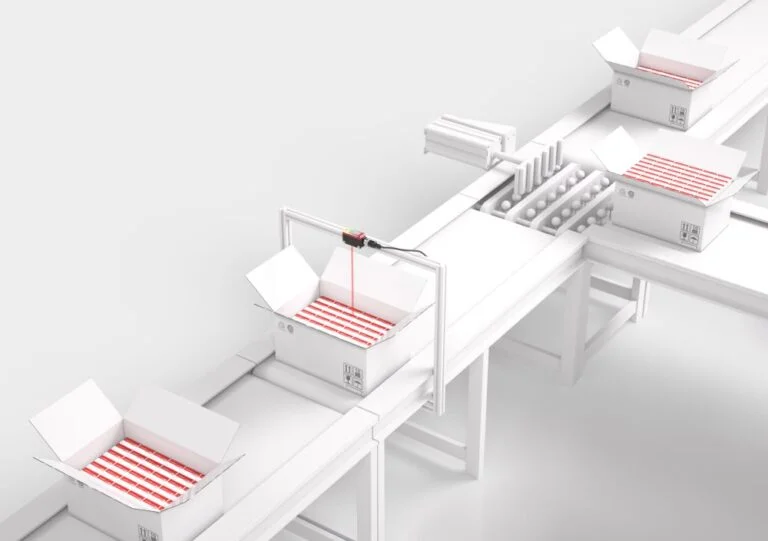

Packing: vacuum packers of chamber type, thermoforming machines, tracers

Washing of tare: machines for cleaning boxes and inventory

Sanitary and hygienic equipment: dryers, washing and disinfection

Read More